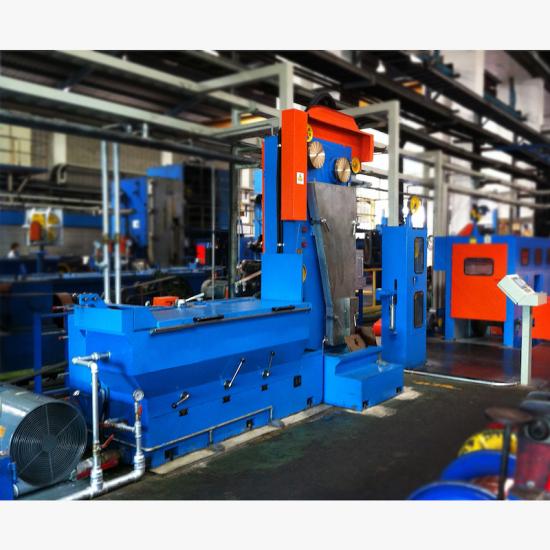

Aluminum Rod Rewinder Type FLP-1400

Product Description:

The aluminum rod rewinding machines mainly used to rewind the ø9.5mm electrical aluminum rod. It rewinds the framed electrical aluminum rods which are produced in continuous casting and rolling process into dense arrangement of ø600×ø1400×ø 900 in bundle to easy for long-distance transportation.

Specification Parameters:

|

Diameter of rod |

9.5mm |

|

Max. speed of spool |

59.4rPm |

|

Max. linear speed of (empty) spool |

2~3.5m/s |

|

Range of row pitch |

10.6~13.5 |

|

Size of coil |

φ1460×φ650×1000 |

|

Size of coiled wire bundle |

φ1460×φ650×1000 |

|

Weight of coil |

1800kg |

|

Total length of rod |

9500m |

|

Main motor |

7.5/1500 AC frequency conversion |

|

Spool moving motor |

1.5/940kw/rpm |

|

Total weight of equipment |

5700kg |

|

External dimensions of the device |

9000×4310×4540 |

Description of the structure:

(1)4000mm - pay off stand:

The 4000mm pay-off stand is composed of welding stand, wire protection tube, bobbin winder. The brackets are welded by the steel; the rods are leaded out through the center line of wire protection tube, preventing the rods disorder; the roller bearings settled in both sides of over-cable drum rotate flexibly to prevent rods' scratching.

(2)Entry sheave:

Entry sheave is made up by welding stand and guide roller. The guide roller guides the rod into straightening device to make the progress more stable of rod.

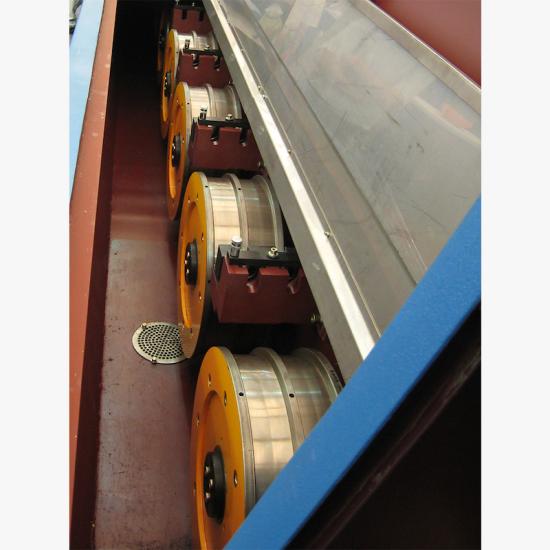

(3) Alignment device:

The alignment is consisted of 4-group mechanism. The first group is "Well" shaped to straightening roller. The space of the roller is large mainly carries on the pre alignment and guiding on the initial stage when the deformation rod is larger. The second group is complex "well" shaped to straightening roller, but the space is smaller and then pre alignment of rod again. Third group is vertical straightening wheel, the straightening wheel are arranged staggered. There is no space for Aluminum rod and straightening wheel. According to the characteristic of rod material deformation, it will adjust the position of straightening wheel, making the rod bear the pressure between the wheels to achieve the goal of vertical precise straightening. Giving appropriate rod tension by adjusting the elasticity of tension blocks friction. Fourth group is horizontal straightening wheel. The structure is the same with vertical straightening wheel to make the rod can precise alignment in horizontal direction.

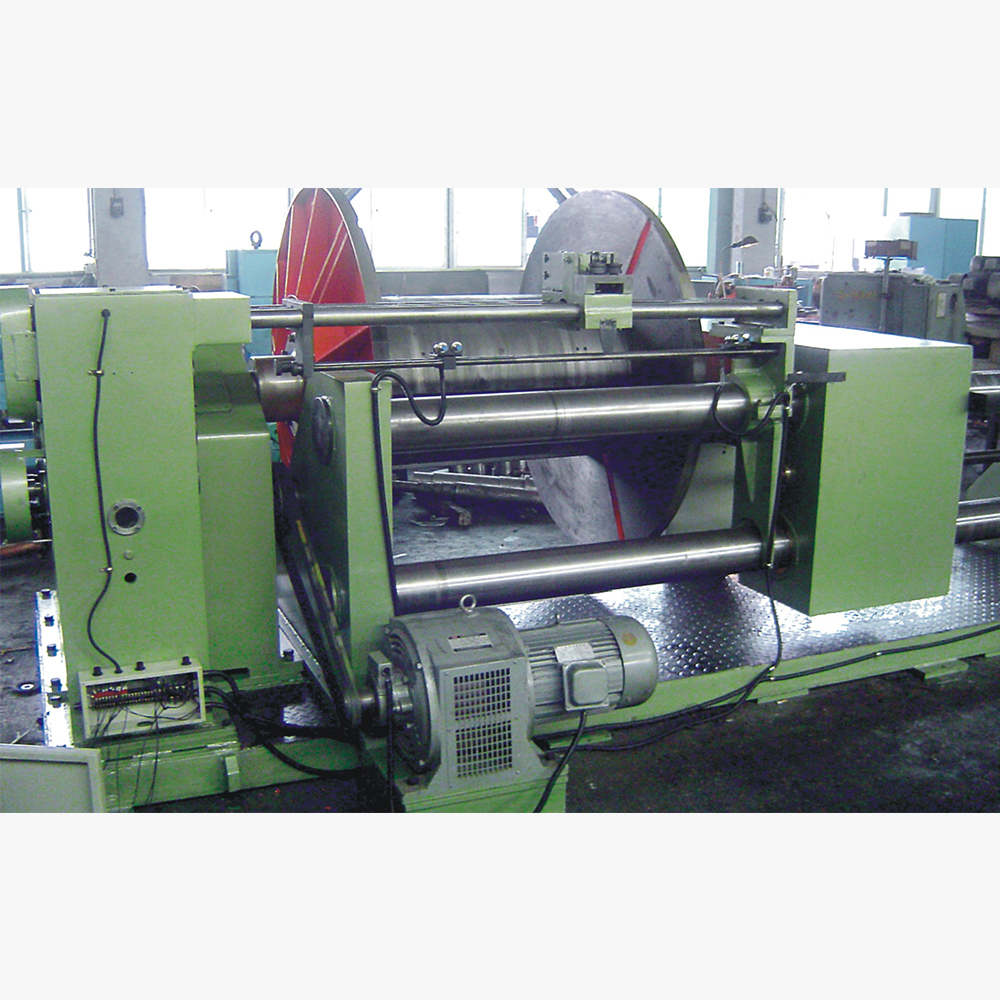

(4)Take-up device:

The take-up device is consisted of bracket, transmission system, winding displacement and basket coiler. The transmission drives are vertical transmission by an AC motor system-18.5KW to make the basket coiler revolving through gear reducer and the basket coiler rotates through the reducer.

Basket coiler is vertical. Upper edge can be dismantled to make the coiled rod unloaded. Inner core is composed of 3 arc plates, through the connecting rod mechanism to shrink and expansion, it is convenient for upper and lower.

Winding displacement part consists of a main drive shaft get in through a set of chain wheel transmission, and through the worm gear reducer, stepless gearbox drive to make the winding displacement rod moves up and down. winding displacement rod is two-way screw rod to realize direction change automatically. Swing Arm Type guiding wheel makes the rod and take-up device closer. It is good for the steady of the progress.

(5)Electrical control system:

The electrical system consists of a three-phase four wire 380V, 50Hz, low-voltage network power supply, the total power of the device is about 18.5kw.

The main motor of 18.5Kw adopts Huichuan all digital AC frequency conversion control.

In 2003, Ito-sin(DeYang) Wire & Cable Equipment Co.,Ltd. was awarded the certificate of quality administration system issued by Britain DAS authority and the certificate of quality administration system approved by Britain UKAS authority. In 2005, it was approved by the international wire & cable association as one of the standing members.

Application and composition:

1.Aluminum Rod Rewinder is used to rewind aluminum rod or copper rod from casting & rolling line and make it regular so as to bundle it up in good order.

2. The equipment is consists of 4000mm-pay off stand, alignment, take-up device and electric control system.

FAQ:

Q1. What information should I let you know if I want to get a quotation?

A: Item Name,Size,Initial Quality you require.

Q2. How to make the payment?

A: T/T

Q3. When will you deliver the machine?

A: Delivery Time for 3 months.