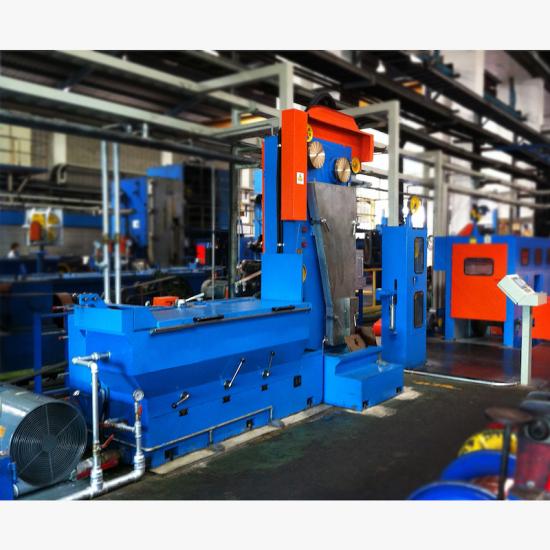

Compact Coiler Type JSM-1000

Product Description:

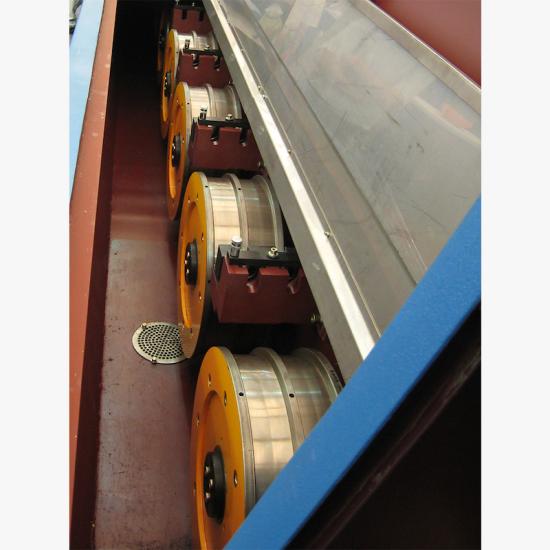

The JMS-1000 compact wire take-up machine is a compact high-speed wire take-up equipment, which is suitable for the finished copper flexible wire, soft and hard aluminum wire and coated finished wire after continuous annealing. The independent take-up system can be used with any brand of continuous annealing production line. The main machine of the take-up machine is driven by a 45KW DC motor and a high-speed imported V-belt drive. The cable is driven by a precision ball screw, and the servo AC motor drives the cable device to reverse and reverse on the linear guide. Through automatic tracking and adjustment of the row pitch, the wire stroke is adjusted by using a micro motor to drive the screw to change the distance of the stroke switch. The clamping spool adopts full hydraulic control, which is safe and reliable; the brake is an air hydraulic disc brake. The control panel of the take-up machine adopts a touch screen operation mode, and is also equipped with a separate emergency stop switch. The safety protection switch and brake system on the protective door can be connected with the emergency stop system of its supporting equipment to ensure the safety of the production process. The take-up spool adopts the expansion screw fastening structure, and the installation and disassembly with pneumatic special tools is simple and fast. The wire reel is hoisted with an expansion jack telescopic structure, which is safe and reliable for hoisting. The operation of the whole machine is simple and convenient.

The use of JMS-1000 compact wire take-up machine, due to the few guide wheels passing through when winding, the surface quality of the finished wire and the elongation of the flexible wire are small. After winding, there is no need to equip a large number of special reels, product packaging and transportation are convenient, sealed packaging, anti-oxidation, can greatly extend the shelf life of the annealing cord, expand the product sales area, convenient export, and can reduce the transportation cost The damage to product quality during transportation is minimized. The user needs to invest in the reel, which can reduce the use cost and save the user's production space; the double-cone cable arrangement makes the pay-out reliable and simple.

Equipment composition:

1) JMS-1000 close take-up host: 1 set

2) JMS-1000 special trays: 2

3) 1 set of JMS-1000 special wire reel: 1 set

4) One JMS-1000 special transport trolley: 1 set

5) 1 JMS-1000 special turning machine: 1 set

Specification Parameters:

Diameter of wire

1.2-3.5mm standard soft

Max. mechanical speed

1500m/min

Main motor power

45KW

Traversing motor power

1.0KW

Motor power for hydraulic station

2.2KW

Standard spool size

∮1000*∮610(∮525)*590*∮170mm

Standard spool capacity

220kg

Power voltage

50v

Power frequency

50Hz

Overall dimension

2650*1850*1510mm

Features:

1. Trunk take up machine is used behind the wire drawing machine for continuous, uninterrupted production and increasing the productivity.

2. Trunk take up machine with non-rotation drum enabled the finished wire to be taken out continuously.

3. The equipment is very suitable for taking up high intensity wires after drawing.

4. Compared with common take-up machine, it has an additional calibration module that the straightness of steel wire is improved.

5. Its capstan applies water cooling and air cooling, water cooling for calibration module can improve the quality of wire.

In 2003, Ito-sin(DeYang) Wire & Cable Equipment Co., Ltd. was awarded the certificate of quality administration system issued by Britain DAS authority and the certificate of quality administration system approved by Britain UKAS authority. In 2005, it was approved by the international wire & cable association as one of the standing members.

Application:

It is applicable to annealed soft copper wire, hard or soft aluminum wires, and coated finished wires. With an independent coiling system, it is capable of working in conjunction with any rod breakdown machine and annealer.

FAQ:

Q1. What information should I let you know if I want to get a quotation?

A: Item Name,Size,Initial Quality you require.

Q2. How to make the payment?

A: T/T

Q3. When will you deliver the machine?

A: Delivery Time for 3 months.