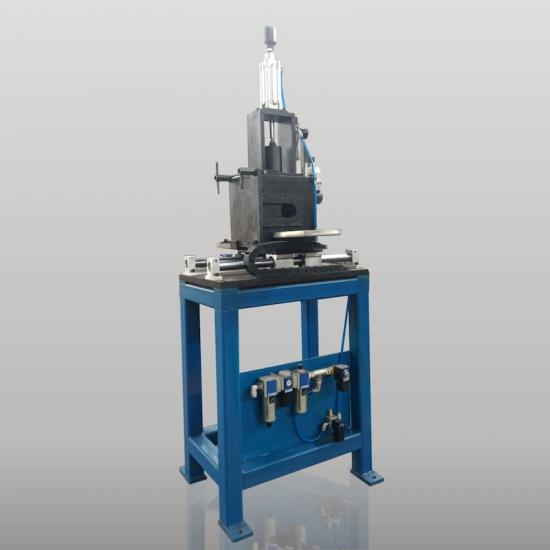

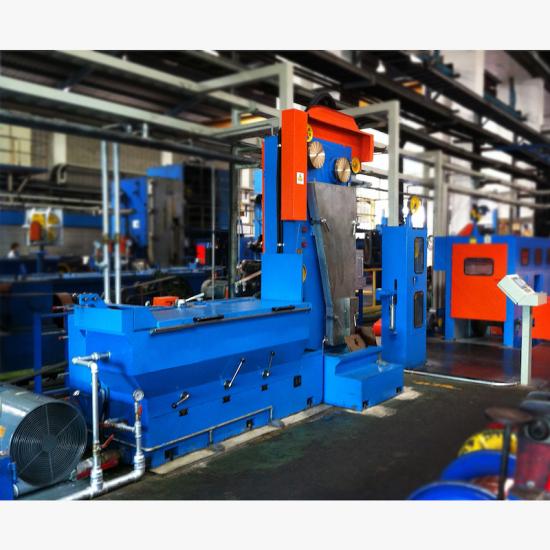

Oil Smearer Type-Z1400A for Overhead Conductor

Product Description:

Production range:

16~1400 steel core aluminum alloy stranded wire

16~1250 steel core aluminum stranded wire

16~1400 gap type stranded wire

We often facing the trouble in the wire production process, apply difficult, using conventional oil coating apparatus can cause uneven coating of oil production, oiled excess or deficiency, workload and other undesirable phenomena, and ultimately affect the production schedule and product line effect of corrosion resistance of the wire. Because the inner layer or layers need to be wire creosote anti-corrosion coating in the twisting step of the overhead conductor, since creosote as a solid fat having a viscosity greater.

In order to overcome the shortcomings in the background technology, our wire oiling machine provides a method and device for oiling anticorrosive overhead wires, thereby solving the problems of uneven oiling of anticorrosive overhead wires and difficulty in cleaning the work area, and reducing operations The workload of employees has improved the anti-corrosion effect of finished wires.

Ito-Sin Wire & Cable Equipment Co., Ltd committed to solve the problem in the past years, now bring our Oil Smearer, and it works well.

Since its establishment, the company has been praised by taxation, industry and commerce, finance and other relevant departments. In 2003, it was awarded the quality management system certificate issued by the British DAS and the quality management system certificate approved by the British Ukas. In 2005, our company was named one of the outstanding members by the International Wire and Cable Association.

Overhead conductor anticorrosive oil coating apparatus comprising: a tank through which the wire, the guide wire lifting device adjusting friction wheel, the regulator is provided with a guide wire and friction wheel lifting device the oil groove, the said lifting device by the lifting guide wheel is rotated, the lift guide wheel bracket rotates, the lift guide wheel rotatable handle configuration, the rotation of the elevating guide wheel guide wheel handle holder is provided with lifting guide wheel is rotated, the lifting spindle is rotated the lifter guide wheel rotation the lifting rod is connected to the bottom; the lifting rotatably provided on both sides of the first fixed guide wheel rotatable guide wheel, a second fixed guide wheel is rotated, the first fixed guide wheel rotatable with the second fixed guide wheel is rotated into the upper end of the contacting the bottom level of the lead tank, provided with a third upper horizontal wire fixed guide wheel is rotated, the third fixed guide wheel rotatably positioned between the second fixed guide wheel is rotated and the horizontal conductors piercing sump; ends of the oil sump through lines perforation lines are provided with inlet and outlet ends of the nozzle through the nozzle, the nozzle opening into the nozzle hole plate through oil groove, the outlet end of the nozzle through the nozzle opening located in the oil sump plate wells, sump plate hole Site should be provided with a rubber grommet wiper pad; said inlet nozzle is a high-strength nylon line into the nozzle.

Advantage:

The corrosion-resistant overhead conductors Oil Smearer before installation of the device with a wire stranding machine production twister each segment, the wire passes through the four cabinets rotatable guide wheel, when the wire moves forward, the friction of rotation of the wire guide wheel next, driven guide wheel is rotated, uniformly coating the surface of the wire creosote solves the overhead conductor anticorrosive oiled unevenness, difficult work area cleaning difficulties etc. , to minimize operator staff, improving the finished wire preservative effect, With full intelligent temperature control tracking technology and control display function! Meet the customers' process requirements!

2003, Ito-sin(DeYang) Wire & Cable Equipment Co., Ltd. was awarded the certificate of quality administration system issued by Britain DAS authority and the certificate of quality administration system approved by Britain UKAS authority. In 2005, it was approved by the international wire & cable association as one of the standing members.

Application and Scope:

1.It’s suit for naked conductor to improve the life service of conductors in electric transmission line

2.Oil Smearer is widely used for 16~1400 steel core aluminum alloy stranding wire, 16~1250steel core aluminum stranding wire, 16~1400 gap shaped stranding wire

FAQ:

Q1. What information should I let you know if I want to get a quotation?

A: Item Name,Size,Initial Quality you require.

Q2. How to make the payment?

A: T/T

Q3. When will you deliver the machine?

A: Delivery Time for 3 months.