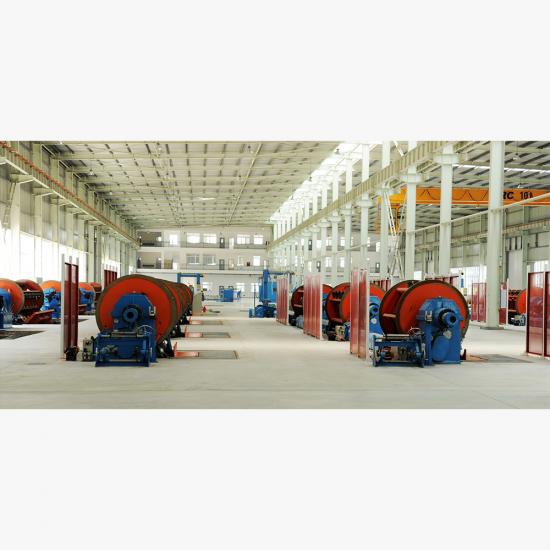

Rigid Frame Strander JLK12+18+24/630

Product Description:

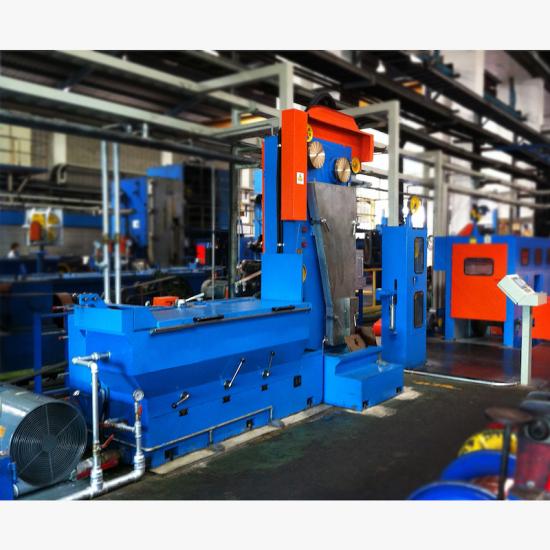

Rigid frame stranding machine, a kind of cage type wire stranding machine, is suitable for stranding round, compressed, compacted Al, Cu and aluminum alloy conductor with die or roll with long length and large cross section; stranding high quality strander conductor for low, medium and extra high voltage (EHV) power cables; stranding prespiralled, straight sector shaped, milliken conductor; stranding overhead conductor ACSR, AAAC, AAC; Copper screening of power cables; Steel wire, strip armouring.

The equipment features high rigidity, high power and high speed. Itso-sin(DeYang) Wire &Cable Equipment , stranding machine manufacturer, can also provide configurations for this cage type stranding machine in accordance with customers’ requirements.

Stranding compressed, compacted round or sector shaped ( straight or pre-spiraling ) as per customer requirements.

We also customise this cage type stranding machine in accordance with customers’ requirements.

Specification Parameters:

Stranding single wire diameter

Cu ∮1.5~Ф4.8mm

Al ∮1.8~Ф5.0mm

Max stranding cross sectional area

Cu 630mm

Al 1000mm

Max. speed of cage

12-bobbin at 67~156 rpm

18-bobbin at 57~133 rpm

24-bobbin at 48~112 rpm

Stranding pitch

38~950mm

Linear speed of pulling capstan

6~44m/min

Power of main motor

132kW

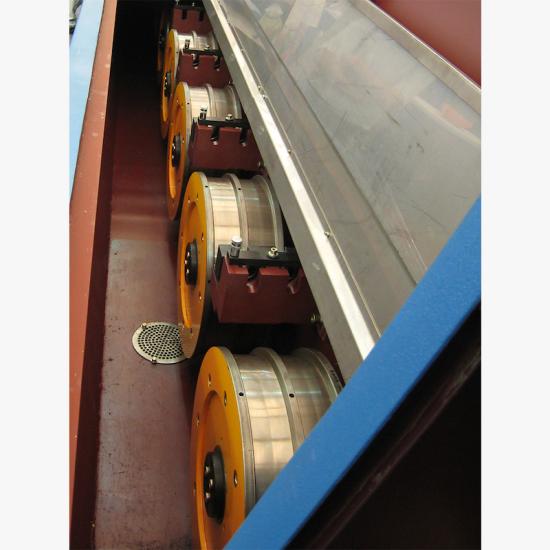

Size of pay-off bobbin in cage

PND630

Size of pulling capstan

∮2500mm

Max size of take-up spooler

PN3150

Size of pay-off spool

PN1600

Total length of machine

43m

Total weight of machine

75t

Features:

1. Rigid frame stranding machine adopts Heavy duty frame type Stranding cage, cage supported on self aligning roller bearing on both ends. Totally enclosed gear, centralized lubricating system for bearing, drive to cages. Which improves the smooth operation and reduces noise.

2. The rigid stranding machine adopts a constant tension pay-off device for each bobbin to ensure its quality.

3. This frame type strander is of high mechanical strength, high reliability, high production efficiency, low energy consumption, compact structure and easy operation.

4. Motorised / manual bobbin pintles with safety interlock. Wire-break detection installed for each bobbin.

5. The rigid strander adopts frequency converter motor drive that realizes stepless speed regulation, smooth start, no impact when replacing spools and no damage to the machine.

6. Manufactured by using materials from domestic and abroad famous factories, the wire stranding machine has long usage life.

In 2003, Ito-sin(DeYang) Wire & Cable Equipment Co.,Ltd. was awarded the certificate of quality administration system issued by Britain DAS authority and the certificate of quality administration system approved by Britain UKAS authority. In 2005, it was approved by the international wire & cable association as one of the standing members.

Application:

Rigid frame stranding machine is mainly used to twist ACSR (Aluminum Conductor Steel Reinforced), bare copper or aluminum conductor, and insulated strands. It is the ideal equipment to produce a variety of stranded wires without back-twist. This cage type stranding machine possesses high mechanical performance, complete auxiliary function, large capacity of bobbins and high production efficiency.

FAQ:

Q1. What information should I let you know if I want to get a quotation?

A: Item Name,Size,Initial Quality you require.

Q2. How to make the payment?

A: T/T

Q3. When will you deliver the machine?

A: Delivery Time for 3 months.