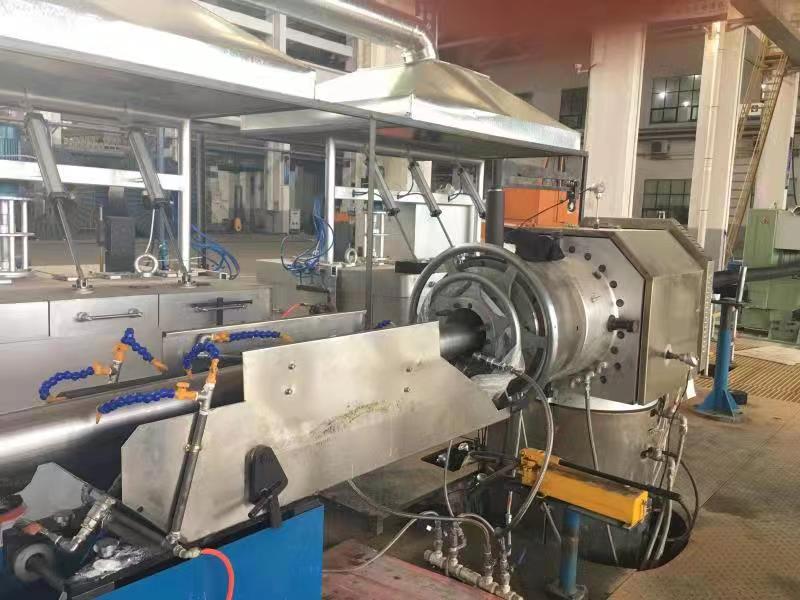

The first two blogs introduced eight main features of continuous lead extruders. This blog will introduce the features of the remaining main components (take the YQL-Φ100 / 5 continuous lead extruder as an example):

9. Rear Water Cooling System

It consists of cooling water spraying pipe and subsequent spraying pipe for stainless steel laundry, which can make the second cooling for the crystallization of lead layer and crystallized lead sheath at the exit of die.

At the rear of laundry is mounted air compressed wiper to dry the surface of lead sheath.

10. Flow Controller (including full automatic auxiliary system)

The cooling water pumped out of the bottom of the machine enters into the extruding barrel in 3 lines through 3 glass rotameters in coordination with the heaters, inlet water is adjusted by manual which can control the process temperature of extruding barrel.Flow meter is equipped with the valve for adjustment, and on it water flow on each cooling point of machine can be read.

Proportional valve for full automatic auxiliary system is Siemens, China

11. Electrical Control System

Touch screen exchanges data in dual ways through PLC, controls and monitors the system via PLC process. Output of PLC is transmitted to each speed regulator to control and monitor status of each device to carry out control in computer.

|

Power source |

380V,50Hz |

|

Total installed capacity |

195KVA(excluding pay-off & take-up, etc.) |

|

Speed regulator for AC motor |

G120 series , Siemens, China |

|

Temperature controller |

RKC, Japan |

|

General low voltage device |

within63ASchneider, France |

|

PLC |

S7-1200 series , Siemens, China |

|

Touch screen |

“WEINVIEW”10`` color |

|

Display on Touch screen |

1.main machine and auxiliary devices 2.Temperature of each heating zone and set status 3.Automatic proportional valve and set status 4.Heating faults and motor faults 5.Illustrated pictures for each heating zone for watching easily and directly 6.Cooling water temperature and liquefied lead level 7.Shift for auxiliary pumps

|

|

Display on recorder(equipped with printer port to collect the data) |

1.Current of main machine and diagram of rotary speed 2.Temperature diagrams of upward, middle and below extruding barrel 3.Linear diagram(signal from spooling dancer) 4.Diagram of Upward, middle and below automatic proportional valve 5.Oil temperature diagram of gear box |

|

Alarm |

Abnormal control of main motor, low pressure or over temperature of lubricant oil |

|

Control of feeding material for pot |

Automatically open feeding motor after liquefied lead alarm |

|

Electrical control cabinet |

Fully closed structure similar to Rittal, equipped with air condition to ensure the cleanness in cabinet and normal work of system |

|

Heating for omega pipe |

Adopt jumping heating method to ensure normal work |

|

Heating die stock |

Divide into three zones to ensure easy operation |

The main components of the company's continuous lead extrusion machine have been introduced. If you have any questions, you can make further consultation. The continuous lead extruder of our company has always won the favor of major cable companies. The reason is not only the good quality of our products, but also the services provided by the company. The company adheres to the principle of customer first, and serves customers at home and abroad in order to achieve a win-win situation.

categories

recent posts

scan to wechat: